Efficient processes and maximum transparency - benefit from the advantages of a system supplier.

Applying the state-of-the-art joining techniques to our assembly process, we combine components into entire modules and systems in large and small production runs. Simple, transparent, lean processes that are customer and product oriented and all assembly services are combined efficiently into one single cycle (one-piece flow).

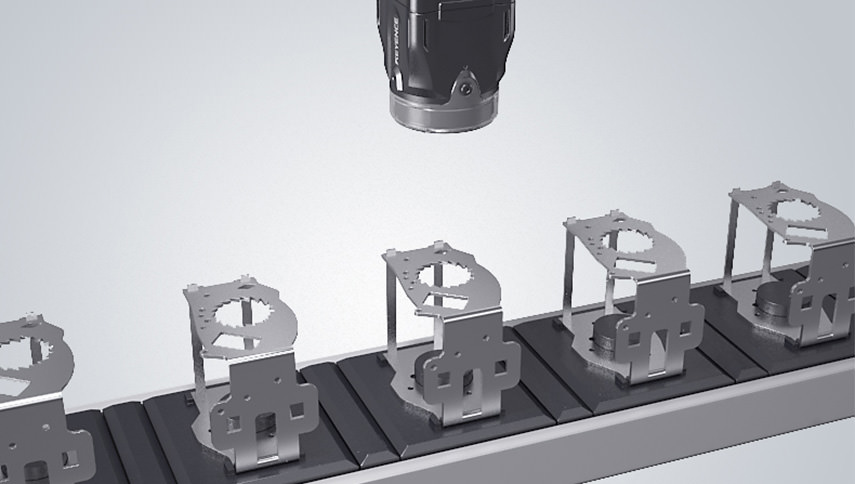

Depending on the size of the production run, product and joining technique, we check what level of automation is most practical for your product. In this process we pay special attention to ensuring full batch traceability, safety along the entire process chain and therefore, we can offer you all product-relevant processing, finishing and testing processes at the production site.

Additional processing techniques

We are experts for a wide range of component and system processing techniques. Ranging from thermic joining to computerised milling machines.

- Ultrasonic welding

- Mirror welding

- Resistance welding

- Gluing

- CNC grinding

Surface finishing

We put the finishing touch to your products using precise finishing techniques, which are also fully integrated in our production chain.

- Chromium plating

- Coating/painting

- Electroplating

- Electrostatic shielding

- Vapour deposition

- Pad printing

- Hot stamping

Downstream inspection process

On the basis of our “zero-error principle”, we inspect the components, modules and systems under series conditions for compliance with the specification sheet.

- Partial and fully automated leakage test

- Visual check

- Operating test and inspection of modules