Engineered plastic parts and modules for almost any installation space, specifications and legal requirements.

Demands placed on plastic parts are increasing, tolerances are becoming tighter and more complex dimensional measurements must be made. As a long-established partner to the automotive industry we develop and manufacture high-precision automotive parts and modules – from small to large batches.

We never lose sight of your goals and achieve economic efficiency by targeted use of resources. Thanks to product designs, which are optimised for the installation space available, we can attain maximum precision even in the tightest of spaces. Process reliability is ensured by means of lean process chains, certified quality management and in-process measurement.

Lighter, more precise and well thought-out. For the past 80 years, we have brought numerous ideas onto the roads. Some of our exclusive solutions for:

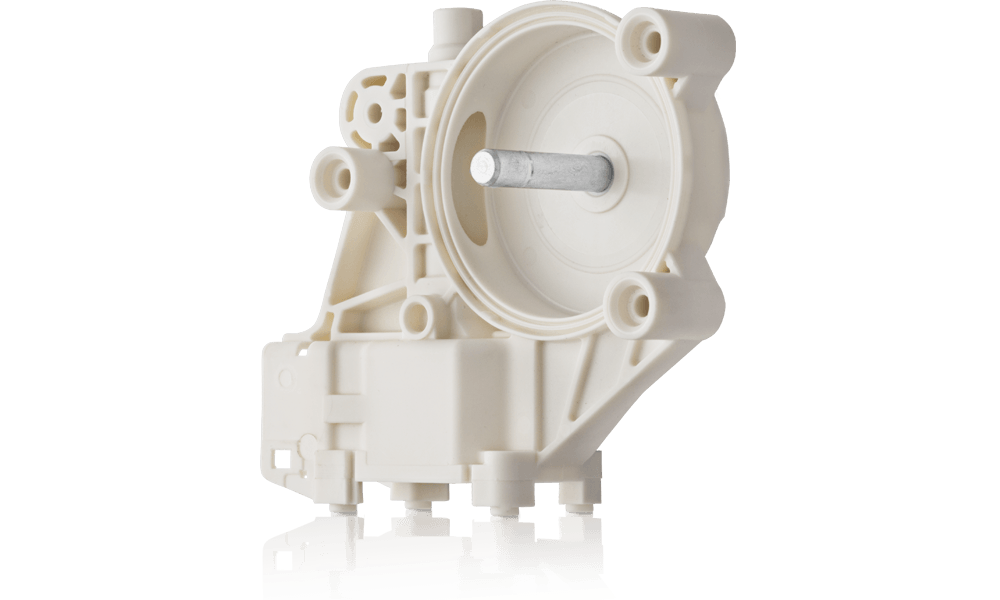

Gearbox housing

Plastic housing with injection-moulded metal axes and electrical contacts

These comfort parts are manufactured in a fully-automated production process and comply with very high specifications for precise contact surfaces, level sealing surfaces and tolerances in order to ensure their correct functioning for the customer.

- Electric windows

- Rear windshield wipers

- Electric parking brakes

- Clutch servo unit

- Seat adjusters

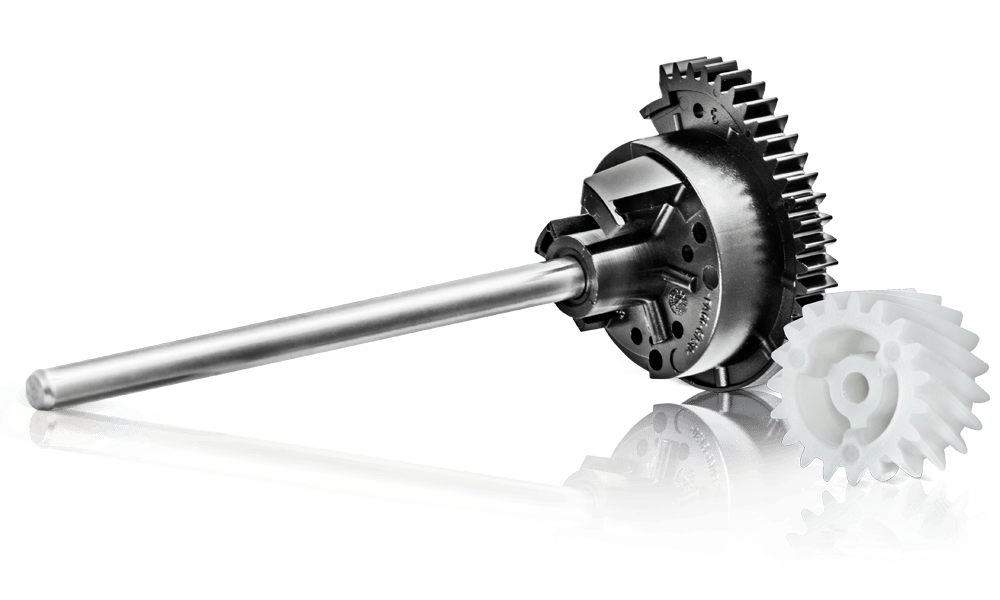

Toothed parts

Gear wheels of various different type with or without metallic inlays.

Targeted material selection and parts dimensioning allow us to implement rugged, noise-optimised toothed parts that are matched to each other and modules, which – as well as their functionality – also help increase driving comfort. You can find our gear wheels in seating adjusters, parking brakes, tailboards, ESP systems, AGR gears, e-gas systems and door-locking systems.

- Cylinder wheels

- Multi-staged gears

- Worm gears

- Non-round gears

- Planetary gears

Pump parts

Housing, control parts and impellers for use in pump applications

Whether in vacuum, diesel or petrol pumps – our engineered plastic parts and modules meet very high requirements regarding surfaces, plane surfaces, sliding surfaces and degree of fitting precision of the communicating components. To extend the life of components, thermo- and duroplastic materials with very high wear and fluid resistance come into use.

- Pump housing

- Control elements

- Impellers

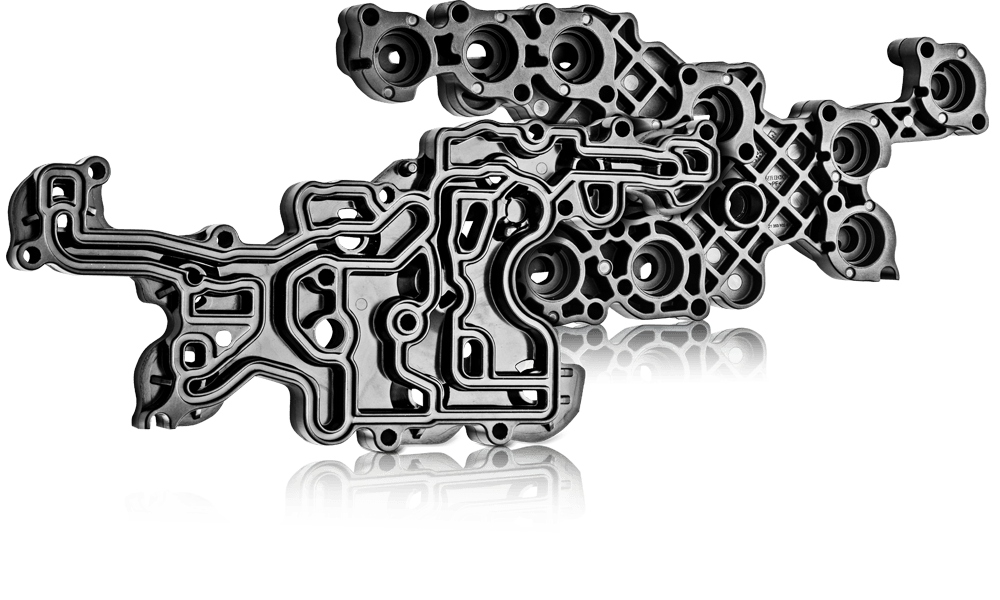

Gearbox and clutch technology

Highly-durable engineered components and hybrid modules for gearbox and clutch applications.

Every day, our products prove their worth in various high-performance gearboxes, torque converters, control systems and clutches. Highly-durable, temperature-resistant and materials with improved friction properties are put to use to meet the especially stringent requirements placed on strength, tolerances and operating capability in this sector.

- Injection-moulded metal shift forks

- Guide wheels

- Control pistons

- Bearing- and guide sleeves

- Master cylinders

- Hydraulic cylinders

Other areas of application

From the engine environment to the steering system

Numerous additional uses for our products can be found in thermal car management, engine control systems, steering and driver-assistance systems.

- Control parts for ventilation flaps

- Sensor housing

- recordings for visual image recognition

Our customers include almost all known TIER1 suppliers, system manufacturers and OEMs in the automobile industry. Including: